#rubber material

Explore tagged Tumblr posts

Text

best rubber maufactrur in ahmedabad - vivekrubberindustries.com/demo/

Vivek Rubber Industries is known for its high-quality products and excellent customer service. We have a team of experienced and qualified professionals who are committed to meeting the needs of their customers. The company also has a state-of-the-art manufacturing facility that is equipped with the latest technology. Our Vivek Rubber Industries is a valuable asset to the Indian economy and plays a significant role in the country’s rubber industry. The company is also a major exporter of silicone rubber products and has a strong presence in the global market.

#rubber moulding#rubber manufactring#silicone rubber#rubber products#rubber material#all rubber products

2 notes

·

View notes

Text

Unlocking the Secrets of Rubber Lining: A Comprehensive Overview

Rubber lining is a critical process in various industries, providing protection against corrosion, abrasion, and chemical damage. In this comprehensive guide, we delve into the intricacies of rubber lining, exploring its applications, benefits, and best practices for optimal performance.

Understanding Rubber Lining

What is Rubber Lining?

Rubber lining involves the application of a protective layer of rubber to surfaces exposed to harsh environments, such as tanks, pipelines, and industrial equipment. This layer acts as a barrier, shielding the underlying material from corrosive substances and abrasive elements.

How Does Rubber Lining Work?

During the rubber lining process, specially formulated rubber compounds are applied to the surface of the substrate using techniques such as spraying or vulcanization. The rubber material bonds securely to the substrate, forming a durable and resilient protective barrier.

Applications of Rubber Lining

1. Corrosion Protection

One of the primary applications of rubber lining is corrosion protection. Rubber-lined surfaces are resistant to a wide range of corrosive substances, including acids, alkalis, and salts, making them ideal for use in chemical processing plants, wastewater treatment facilities, and mining operations.

2. Abrasion Resistance

Rubber lining provides excellent resistance to abrasion, making it suitable for equipment and structures exposed to abrasive materials such as sand, gravel, and ore. It helps prolong the lifespan of assets by minimizing wear and tear caused by friction and impact.

3. Chemical Containment

Rubber lining is also used for chemical containment applications, where it prevents leaks and spills of hazardous substances. Rubber-lined tanks, vessels, and containment structures ensure the safe storage and handling of corrosive chemicals, protecting workers and the environment.

Benefits of Rubber Lining

(i) Enhanced Durability

Rubber lining enhances the durability of industrial equipment and structures by providing an additional layer of protection against corrosion, abrasion, and chemical damage. This extends the lifespan of assets, reducing the need for frequent repairs and replacements.

(ii) Cost Savings

By reducing maintenance requirements and minimizing the risk of equipment failure, rubber lining helps organizations save on operational costs in the long term. Investing in high-quality rubber lining can lead to significant savings over the life of industrial assets.

(iii) Versatility

Rubber lining is highly versatile and can be customized to suit the specific requirements of different applications and industries. From standard rubber compounds to specialized formulations, there are options available to meet a wide range of needs.

Best Practices for Rubber Lining

(a) Proper Surface Preparation

Before applying rubber lining, it is essential to prepare the substrate properly. This may involve cleaning the surface, removing rust or existing coatings, and roughening the surface to promote adhesion.

(b) Selection of Suitable Rubber Compounds

Choosing the right rubber compound is crucial to the success of the lining application. Factors to consider include the type of chemicals present, operating temperatures, and the level of abrasion resistance required.

(c) Quality Installation

Ensure that rubber lining is installed by trained professionals using proper techniques and equipment. Quality control measures should be in place to verify adhesion, thickness, and overall integrity of the lining.

Conclusion

Rubber lining is a versatile and effective solution for protecting industrial equipment and structures from a variety of hazards. By understanding its applications, benefits, and best practices, organizations can optimize the performance and longevity of their assets, leading to improved safety, efficiency, and cost savings.

Unlock the secrets of rubber lining and elevate your industrial protection measures today!

#industry#technology#manufacturing#materials#rubber products#rubber industry#rubber lining#rubber sheets#rubber sheet mixing#rubber lining industry#rubber lining solution#rubber lining process#rubber technology#rubber process#corrosion#abrasive coatings#protective equipment#rubber material#manufacturing industry#rubber lining techniques

0 notes

Text

HAVE AT YOU!

#super mario bros#smb#super paper mario#spm#luigi#mr. L#fanart#dreamyart#THIS WAS SUPPOSED TO BE A WARM UP!!! I HATE YOU!!!!!! IHATE YOUUUUUU I HATE WHAT YOU DO TO ME#SHAKES YOU THROWS YOU AT THE WALL KICKS YOU IN THE STOMACH#ahem#poor guy is constantly ripping up his stupid rubber suit#the little red patch is from a previous fight with mario btw#maybe a piece of his shirt or hat got ripped and L just kept it for some reason...? w-why's this red... so... familiar... COUGH#*uses it to patch my suit even though it's entirely different material* *for no reason*#anyway hi

954 notes

·

View notes

Text

[ ive reached a point i am genuinely contemplating giving tf.one verse its own sideblog just, dash only, no theme, etc because he's. he's certainly developing in a way. i dont know what im cooking but he's built different. hmmm...

#it's a rubber band shot away from normal in personality/background#most of the other universes i do are still based on aligned with some tf.a because that's core most developed canon versions#that i love#and apply to other verses with little background material for him because it's easy to do so and usually i can modify without any trouble#[BLUE SPEAKS] ooc#oh god this means i have to come up with a url tho

21 notes

·

View notes

Text

We could've had this heartwarming but comedy ass "fighting over Sobel" scene instead the one we got.

Slow realization when they're fighting for Sobel, then laugh together, then has anyone seen Tab?

12 notes

·

View notes

Note

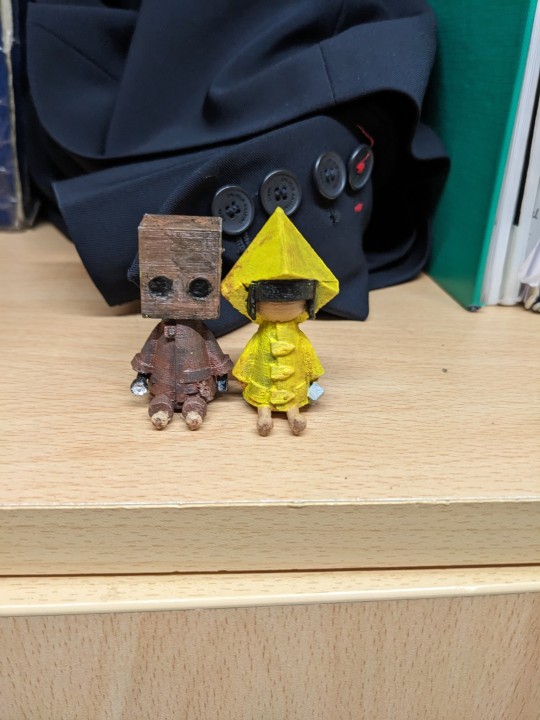

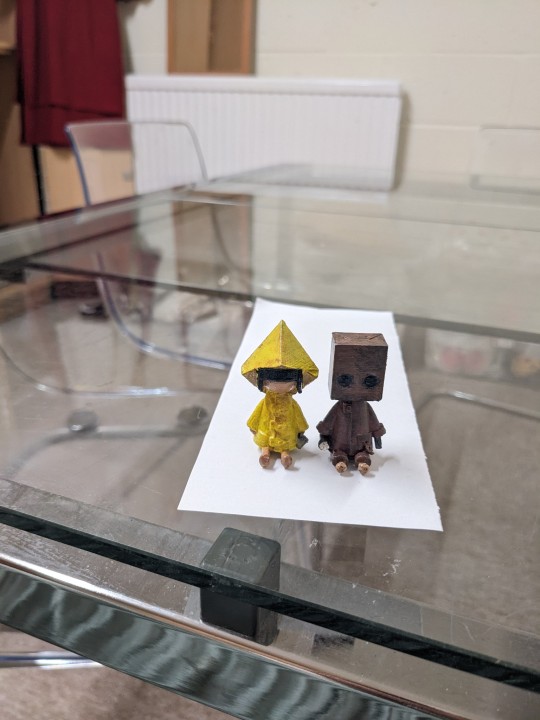

You made your icon? Do you have a bigger picture of them?

Sure! I had to dig through my camera roll for these since I don't have them on hand right now, but here they are, before and after painting!

I made them in with my school's 3D printers, a matching pair for me and my friend.

Unfortunately, they are very small, about 5 cm tall, so the pictures might not help much.

Six's raincoat took so many layers of paint, but it was worth it in the end!

#asks#breanna#thanks for asking!!!! :D#my art tag#the yellow paint is always so much less opaque than the other colours 🥲 whyyyy#also that first picture is how mono printed cause we forgot to turn off support material#it was such a pain to remove lol#he actually had a key on a loop by his pocket before#but it came off with the support :/#oh well. you live and learn#mini-six now lives in my schoolbag and serves as my rubber duck when im stuck on a problem#its surprisingly effective

18 notes

·

View notes

Text

good morning. was eating toast like a normal person just now & the top ball of my tongue piercing unscrewed mid-chew. i swallowed it

#fuck my life this is why i don't eat breakfast#it wasn't a metal one either it's 100% plastic#← the plastic balls are easier on my teeth & lower the risk of gum and tooth damage#plus it had this like... idk rubber material on it? google spiky tongue jewlery#bc it was one of those#luckily the spikes are soft & not sharp at all but how is that gonna hold up in stomach acid bro 😭#sigh. okay rant over

5 notes

·

View notes

Text

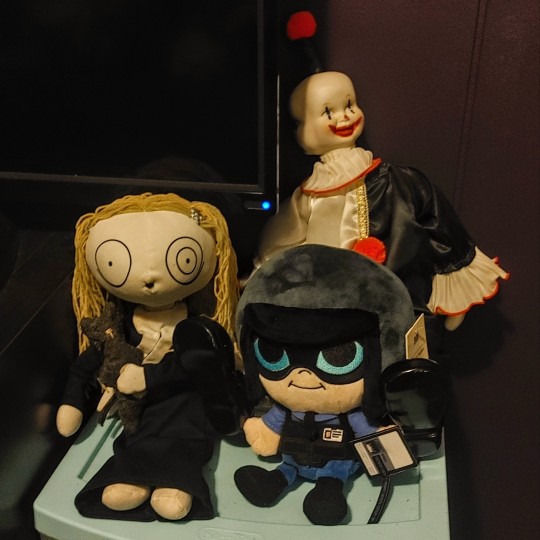

room stuff! im still decluttering tho so i have less n less stuff. rlly no longer interested in my old collection or at least the old disney stuff. keeping SOME of it for sentimental reasons tho ofc<3 i need more wall art tho my walls r Naked mostly

also squeak image , well, shes snoozing

#frank.txt#decluttering is taking so long bc iive been collecting shit since i was young so its hard parting w some stuff#and surprisingly easy to part with other stuff LOL idk im not into a lot of the stuff i was into#i want more spooky things. more Nostalgia Items that i wanted when i was a kid. like emily the strange or begoth dolls n stuff#but begoth dolls r expensive and the emily the strange doll i had when i was a kid is HARD to find now so fhskdhdjd#man that emily the strange doll went thru hell. she was made of a rlly chewy rubber material so i gnawed her arms off bc i was idk 6 or 7#the fewture nirasawa doll i have on my shelf ALSO went thru hell bc i had her since i was 8 but she wasnt chewed on like at all luckily#bc i still have big soft spot fkr that doll#AND the lenore doll i found when i was 9 for like $3 at value village#ANYWAY idk i wanna decorate my room wjth more Spooky Stuff. more wall art n stuff#and jsut have a dedicated raggedy ann corner <3

36 notes

·

View notes

Text

hrghhhh how would you even go about mending an felt and fabricked and metal based animatronic

#disco speaks!#I’m trying to use references cause like they wouldn’t be restored#but they would be cleaned up and repaired/replaced in some way??#like I’m thinking about springtrap btw#like maybe use rubber or a plastic shell (plastic would be prone to breaking) rubber might be too toxic to the actual decayed muscle#and general mummified tight skin/muscle underneath so maybe a silicone based sheet layer?#yeah silicone would make the most sense for that layer#and then having like sort of fire house material or hrmm like neoprene or Kevlar lining on top of that#for general protection#is the casing fully fused to him??#how the fuck does that work#cause with the other animatronics you are just welp child body decays in their and their soul is trapped#so eventually the body is decomposed and essentially no use to the interior and motor functions of the suit#however in springtrap’s case that is not the same#while it can perform on its own it’s meant to have a wearer in it to puppet the movements#so when his body dies does it fuse to just the endo inside??#BUT THERE IS NO ENDO INSIDE??#yeah cause wait#he is the endo of the suit#(skeleton inside a skeleton (skeletonception if you will))#there is supposedly bracing for the spring locks and the interior structure of the suit#I’m still baffled on how it would’ve stood up on its own ngl#I’ve made a puppet head with a metal strap to create the base and then used fabric and foam as a covering#but also that would abrasive I like the idea of the jumpsuit like the movie version has but again material would have been corroded by blood#and other organic fluids as a result of decomposition#like the stomach would have had leaking bile and so would most of the organs due to the punctures#and there is also bladder which becomes loose due to lack of muscle strength so those fluids would take effect#and then the jumpsuit would chafe skin and cause infection as well#well not really infection once deceased but like it wouldn’t help

3 notes

·

View notes

Text

Yes hello I have reason to believe Nathan Wallace's repoman coat is made of rubber, not leather

#too late now im already making it in leather but#I'm pretty sure#repo! the genetic opera#r!tgo#nathan wallace#latertag: or pvc vinyl. this'll probably result in me learning how to sew these materials and making customs one day#latertag pt ii: one of my castmates says its leather but a weird type and idk about that#i think its rubber. ill learn how to work with that one day

14 notes

·

View notes

Text

i know I just reblogged a bunch of posts but this isnt a post just an observation: my phone keeps falling and I think its because they make these cases out of such weird exotic materials and plastics that you think you're putting your phone on a flat surface but 10 minutes later you hear your phone hit the ground and realize that its been sliding at a snails pace imperceptible to you and it moved 2 feet uphill across the desk just to fall.

#our advanced rubber and plastic syntheses no longer obey predictable laws of physics#cats are going to face ecology because they wont have to knock things over off the table anymore after everything is made of these material#cats wont have a space in the home ecosystem when it comes to pushing shit off tables

16 notes

·

View notes

Text

they gotta stop making toxic shit smell so good ugh

#been lowkey obsessed with the smell of rubber cement since 5th grade thanks to my science fair projects#and paint sealer ? and sharpies ? and gasoline ? and mod podge? and rubbing alcohol ? mmmmm#like oh sorry im busy saturday im gonna go huff some hazardous material

11 notes

·

View notes

Text

The soccer ball get nerfed to all heck in the future, dear god, even after snapping the railing like a twig, it then snaps a TREE like a twig. Who knows where its path of destruction ended, because we never see it stop, it may have destroyed half the park as far as we know.

#ch 29#vol 3#The wannabe child murderer is /lucky/ the ball just tore the knife from his grip#Because had it actually hit him; that ball would have tried taking the arm with it and instead just break a lot of bones#Also; my brain supplies that most future 'soccer balls' are just some inflatable rubber and not actually the same material as a real ball#But I don't think a real ball would turn into a cannon anyway. The future inflataball should be just as capable of destruction at max power#And to an extent; is capable of destruction; but it's not been allowed to do anything like exploding a tree#detective conan

5 notes

·

View notes

Text

Anonymous submitted:

"I am not sure what to call whatever that thing covering her nipples. Nipple Curtains or Boob Draperies?"

Yeah, those are like nipple-capes. For when your nipples feel like fighting crime.

Also she's shaped like a bottle opener.

(Art from Langrisser Mobile, Masaya Games & ZlongGames)

66 notes

·

View notes

Text

can't believe one piece of all things is the manga that gets a good live action adaptation. one piece? really? unadaptable one piece? I've seen manga set in the real, modern world with worse live action adaptations than fucking one piece? honestly at this point there's no excuse for that awful netflix adaptation of death note if THIS is what actually caring about adapting manga to live action can look like

#one piece#i don't even go here!#like I've watched a good amount of one piece#(even though it scared me when it aired on toonami)#and I'm so surprised that it actually looks *checks notes* good?#like sure luffy looks silly with his little rubber body but that's true of the manga too 🤣#honestly with this live action finally breaking the manga equivalent of the seinfeld curse#my only question is…how? are they going to adapt? hundreds of manga volumes? with humans???#because last I checked the anime has like more than a thousand episodes#and the manga is probably not ending soon#y'know this is the first time ''too much source material'' has worried me THIS much#cuz it's in typical netflix fashion a pretty short season so i don't really think they intend on adapting ALL the manga#right?#i have so many questions

14 notes

·

View notes

Text

i need to learn how to render/shade rubber and latex and vinyl and pvc and

#such fun materials to work with but they look bland with basic shading#my sona's face [the android body] is made out of rubber it would be fun to draw him slightly more realistic#to bring out the actual fake humanoid robotic look especially on the face

4 notes

·

View notes